There were 17 participants from various nations and all walks of life. For example we had a small wind turbine dealer from Ireland, a vicar, an electrician from Sellafield, an architecture student, a formula one racing mechanic, a GP, a dutch group therapist, a danish energy consultant, an american engineer, a catholic church worker from Uganda, etc.... Matthew cycled all the way from milton keynes to be there.

Thanks to Katie for looking after the metal workshop.

Thanks to Mo for contributing most of these pictures.

Here is the metal workishop. Marking out the steel disks.

renewing the bearings in the wheel hub

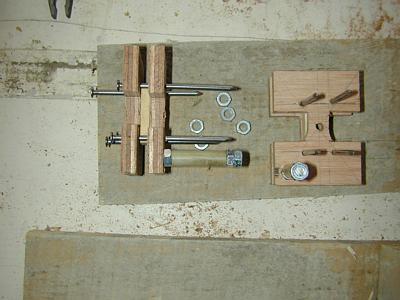

Making the coil winding machine

Mixing resin for the stator casting

putting resin in the statr mould

putting in some fibreglass cloth

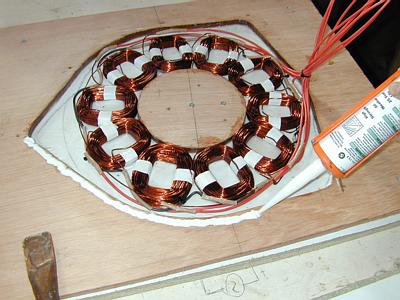

In go the coils. Silicone around the edge to redue leakage of

resin.

Putting the lid on the stator casting.

Painting the magnet disks with resin

Fitting the magnets on the disk

using various tools to compress the lid on the magnet rotor mould.

The magnets pull them down tight.

A finished magnet rotor.

Assembling the alternator

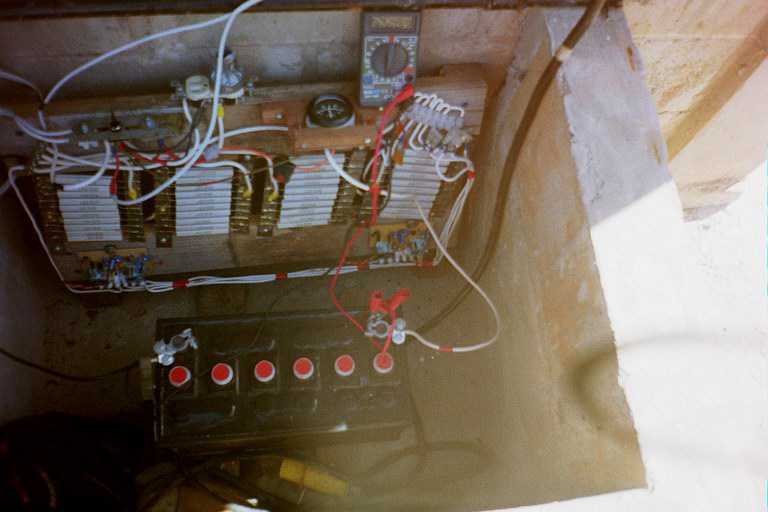

Cranking it up, and testing the output.

Meanwhile the blades were being carved. This is the space we used

for blade carving and resin casting.

Some of the wood had defects, so we had to develop a method to reinforce

the weak place.

Fitting the blades to the alternator.

Erection on site at CAT.

Waiting for wind which never came.

The machine was then dismantled and will be shipped to Nicaragua for

a village electrification project. This was the decision of the group

who built it.

Down at the local pub in in Cynws.

We heard some remarkably good songs, and the notorious squirrel story.