sorry about the quality of some of these pictures - the light was

very poor at times.

metalwork blades

castings assembly

small machine

OR JUST SCROLL DOWN...

We enjoyed the weather and the sculptures in the yard. It was

alo a good place for blackboard sessions.

Drilling out the magnets disks

We centred each disk carefully by rotating it past a stationary object

before drilling through the holes in the hub flange into the disk.

The alternator mounting bracket being fitted to the yaw bearing

setting the correct offset

stator mounting lugs

tail boom (oops john should have eye protection on)

Neil cutting our the blade taper

on a bands

Fitting the back disk to the blades

Drilling clearance holes through the blades

Cutting out the blade root wedges

Cutting very accurate circles with a router

The magnet-positioning jig

Using the jacking screws to lower the front rotor into place gently

Testing the output from the alternator

Testing the output from the alternator

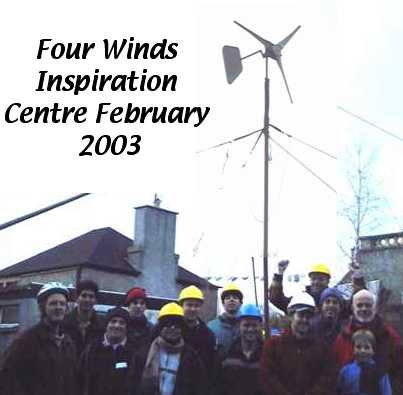

There was no wind when we erected the machine unfortunately.

NEXT COURSE IN EDINBURGH IS

15th-20th March 2004

£300.00 per place. Six day

course

to

book a place - e mail (click here)

or Telephone/Fax:

0131~332~2229

We did some work on a smaller wind turbine using a

single magnet disk and casting a stator on the end of the tubular shaft.

The coils for the small machine