Colin Reid, Leonard Fernando, David Hooper, Keith Wyse, Richard Thomas, Hugh Piggott, John Stuart Bates, Pete Campbell, Bryce Gilroy Scott, Stephen Nolan, Brendan Callaghan, Bruce Luckhurst and Neil Stoddart.

Monica Lewis and John Cosgrove had to leave before the photo. Thanks for all the pictures, John (the ones with enigmatic 2002 dates on them).

We built the usual 2.4 metre diameter machine.

It 's getting harder to find the cavalier hub. Cars are getting more complex.

Bruce and Neil were the resident workshop guys as usual. We're getting good at this.

Bruce shows John Cosgrove and Stuart the cut-off machine.

Stuart replaces the bearings in the hub.

A neat coil winder.

Brendhan winds a coil.

Very tidy coils

Tinning the tails prior to soldering the output leads.

Checking the mould with Colin.

The winding makes it into the stator mould.

Bryce pours in the gloop.

Pete pouring the magnet rotor.

Old saw blades are very good for pulling the lid down onto the magnets.

Keith, Leonard, John and Bryce unveil the magnet rotor.

Keith trims the rag off the casting before knocking out the plywood

island. Watch out fo rthe magnets grabbing the knife!

Placing the small machine's coils in the mould.

Dave working on the small machine stator casting. The plastic bucket in the middle shapes the resin around the shaft.

The small stator came out nicely.

Dave assembles the small machine. Later he took it back to his

houseboat to charge the battery.

Monica carving a blade.

Hugh checking the drop.

Richard holds down the blade while they set the tip spacings.

Stuart drills the blade hub for the larger wind turbine.

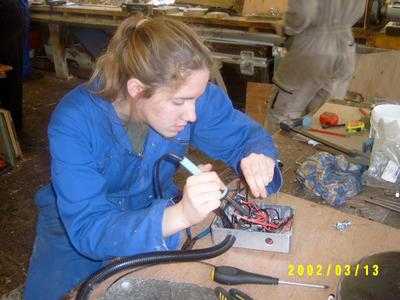

Monica soldering inside the rectifier box.

John fixes the box to the top of the yaw bearing.

Stephen and Stuart fit the stator.

Fitting the front magnet rotor is often a fiddly job. Bryce, John,

Monica and Stuart.

Slackening the jacking screws to allow the rotors to come together.

Stuart checks the air gap with a suitable piece of card. It needs

to be equal front and back of the stator, and about 1.5 mm minimum at any

point. We use the stator mounts to centre the stator and if it is

too close then we remove the front rotor and fit more washers to increase

the overall gap.

Neil loves banging the blade assembly onto the machine. Stuart

using a clamp to assist.

The machine ready for erection. Leonard, Stuart, Pete and Colin

posing

not a breath of wind.......

The machine leaves Four Winds on its way to Sri Lanka where Leonard will put it to good use. Thanks to Neil for building the box.