The coils came out nicely - 400 turns of 0.85 mm

diameter fitted the stator perfectly.

I drew a map of the stator to check the size, and compared the weights

with a simple balance made of wood (with 2 screws).

Dominique did most of the soldering.

We used epoxy coated magnets from Sweden. A flange made the

perfect clamp - but hard to remove!

Dominique draws the outline of the casting so that Pascal can cut off

the ragged edge while still a bit soft.

Detail of the stator mould and coils. Pointed corners this time

for some reason!

Note that the corner mounts are between coils, to make more space.

Et voila...

Centring the stator so as to drill the mounting holes (through the

steel frame)

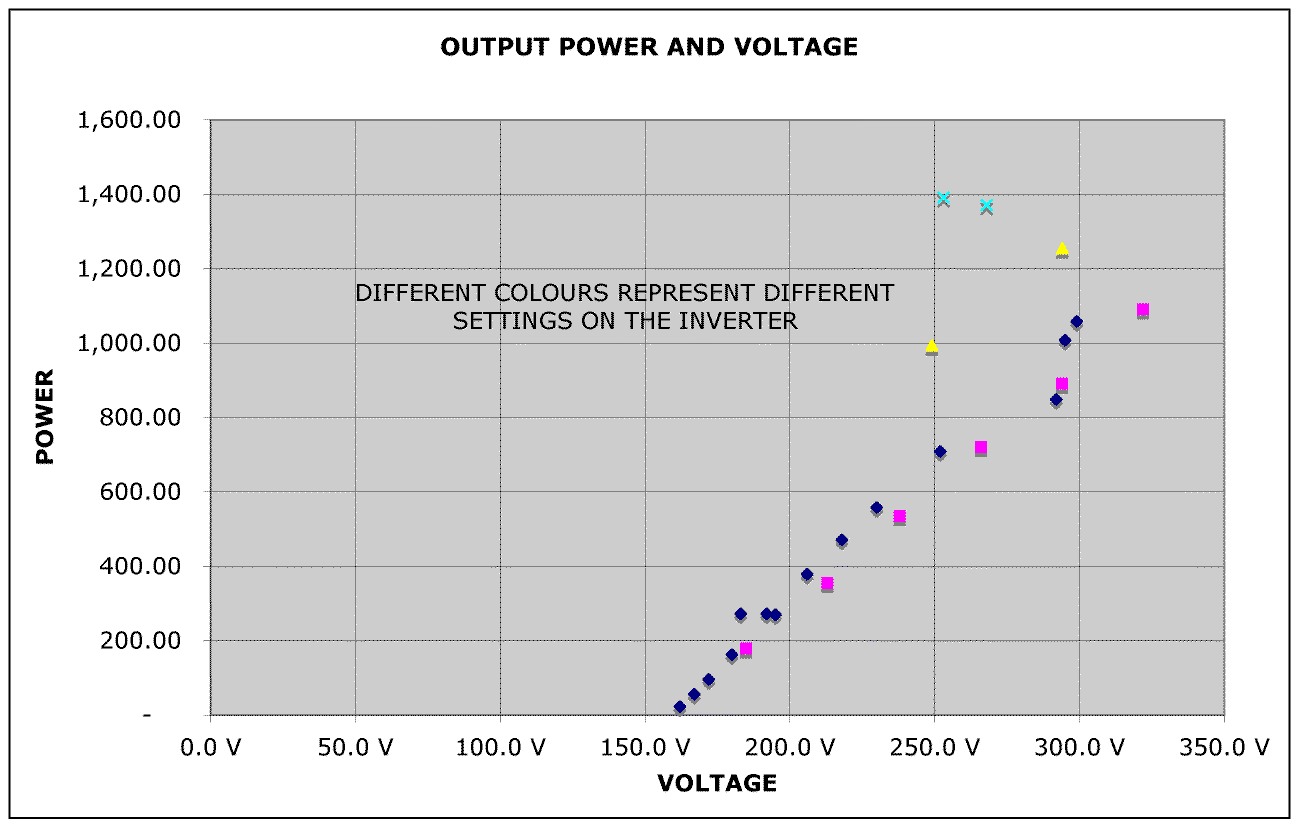

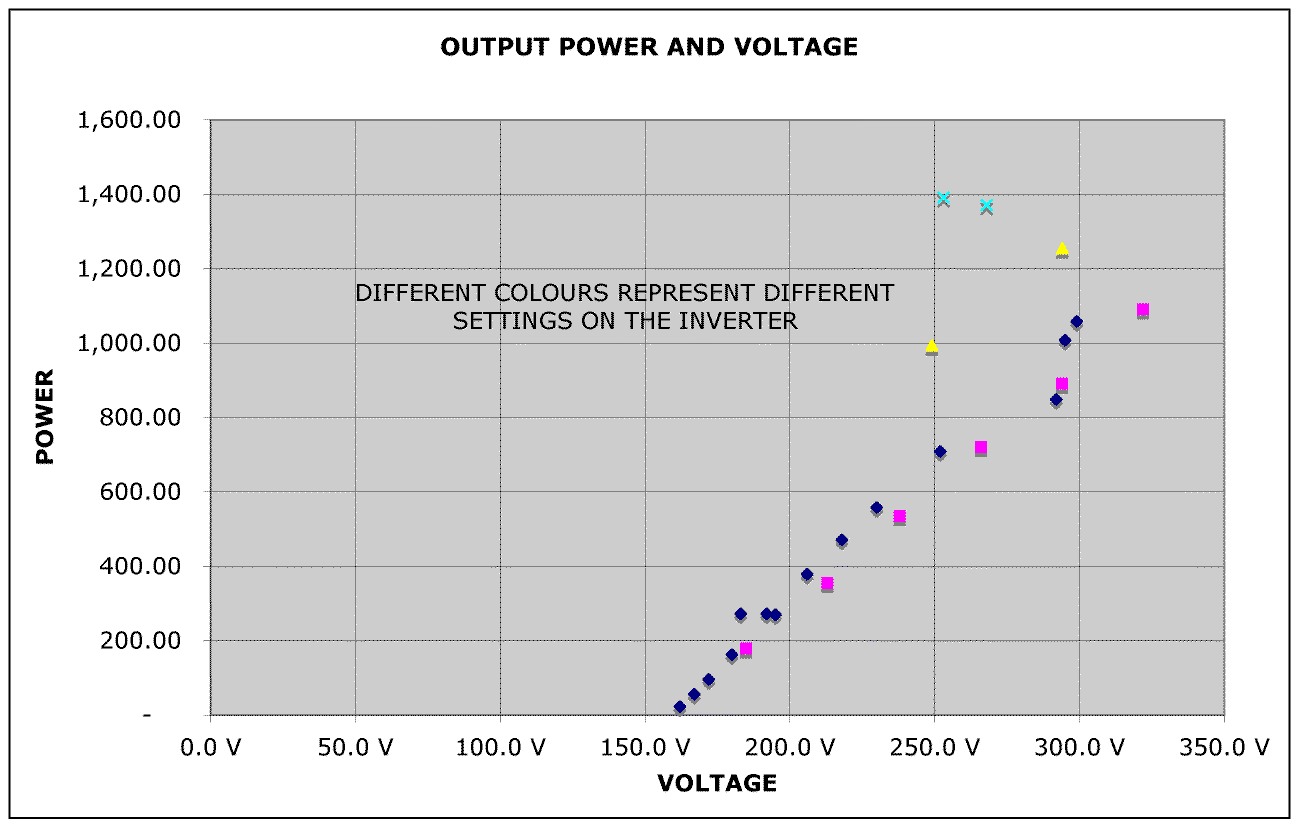

Krug have an excellent bench test rig that runs up to 400 rpm. We

tested with carious 'windy boy' settings and nearly got up to 1400

watts.

Jay programing the Windy boy. Controller by

Tieole

Some explanations of the implications and calculations of the tip speed

ratios.