The machine produced 8kWh tuesday, and was at 9kWh for the

day when the tail broke just before noon Wednesday. The machine had

several ten minute averages of between 1-1.2 kW. Meaning the machine was

quite often producing the maximum capacity of the windy boy 1700.

A new set of blades will be carved in

September and the machine will be installed more permanently after that.

"Shit happens, always check the welds twice" says Jay.

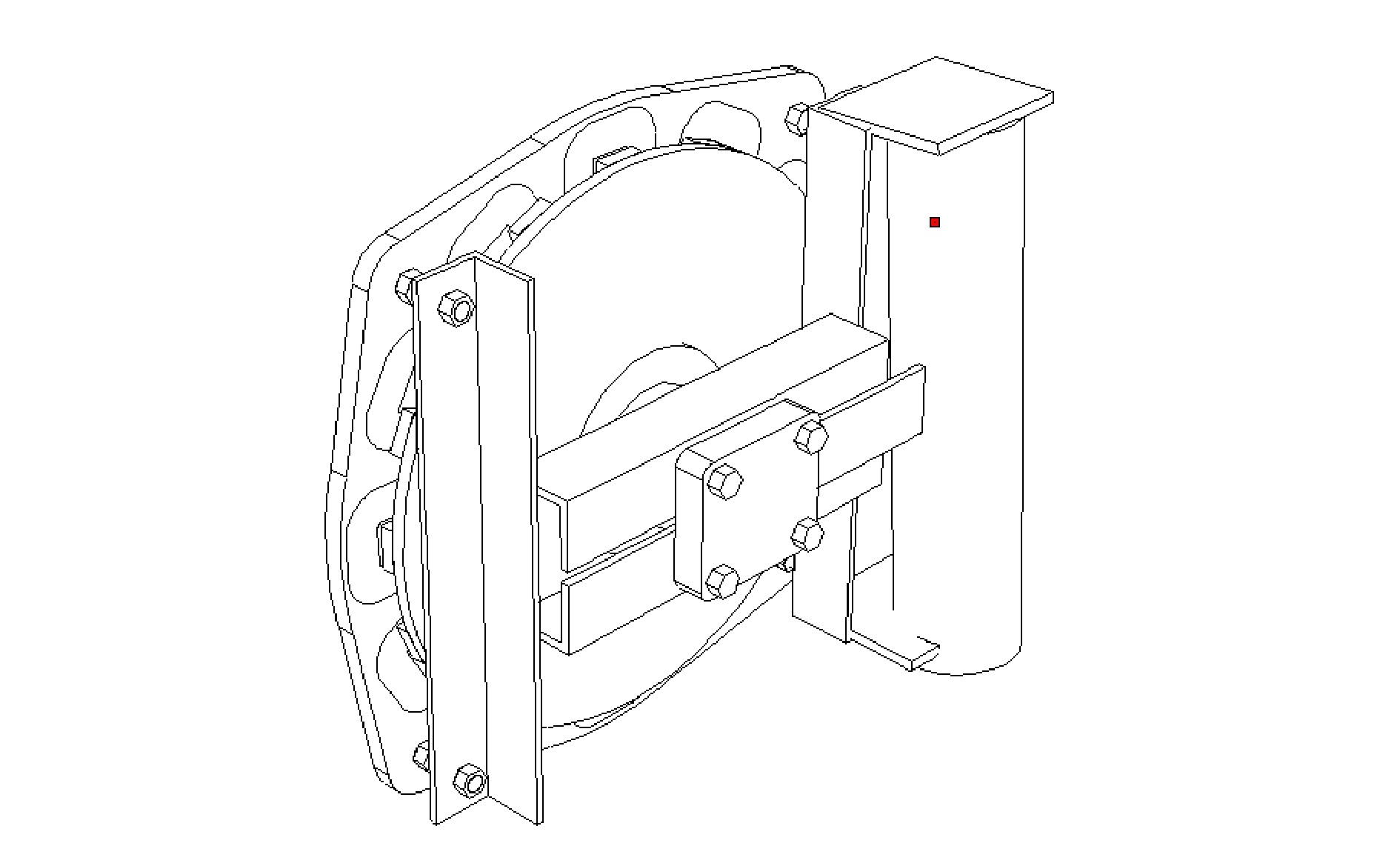

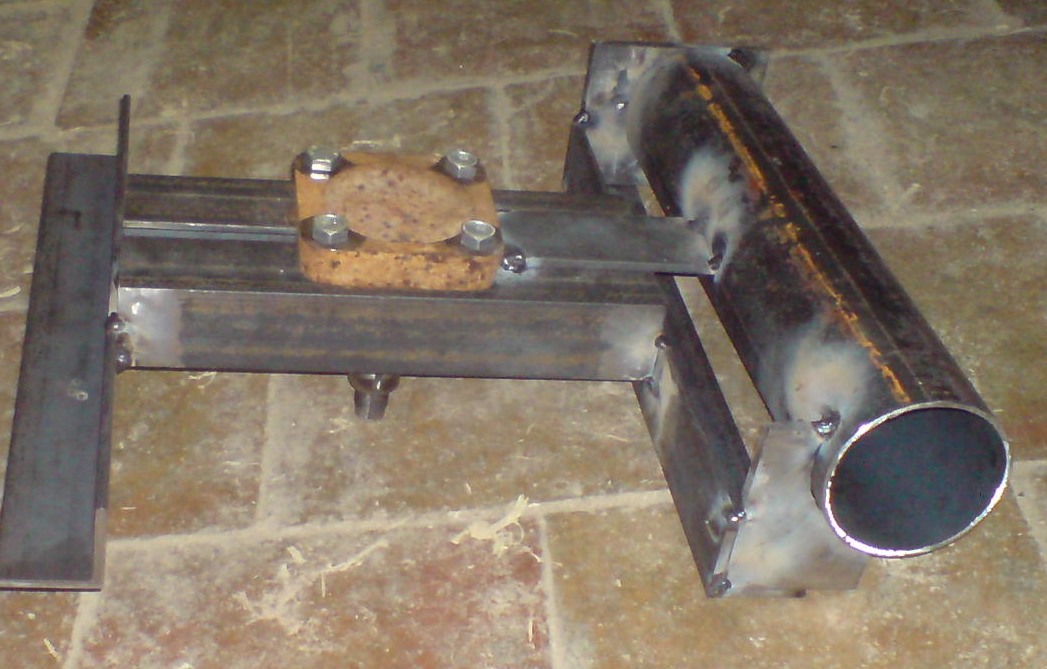

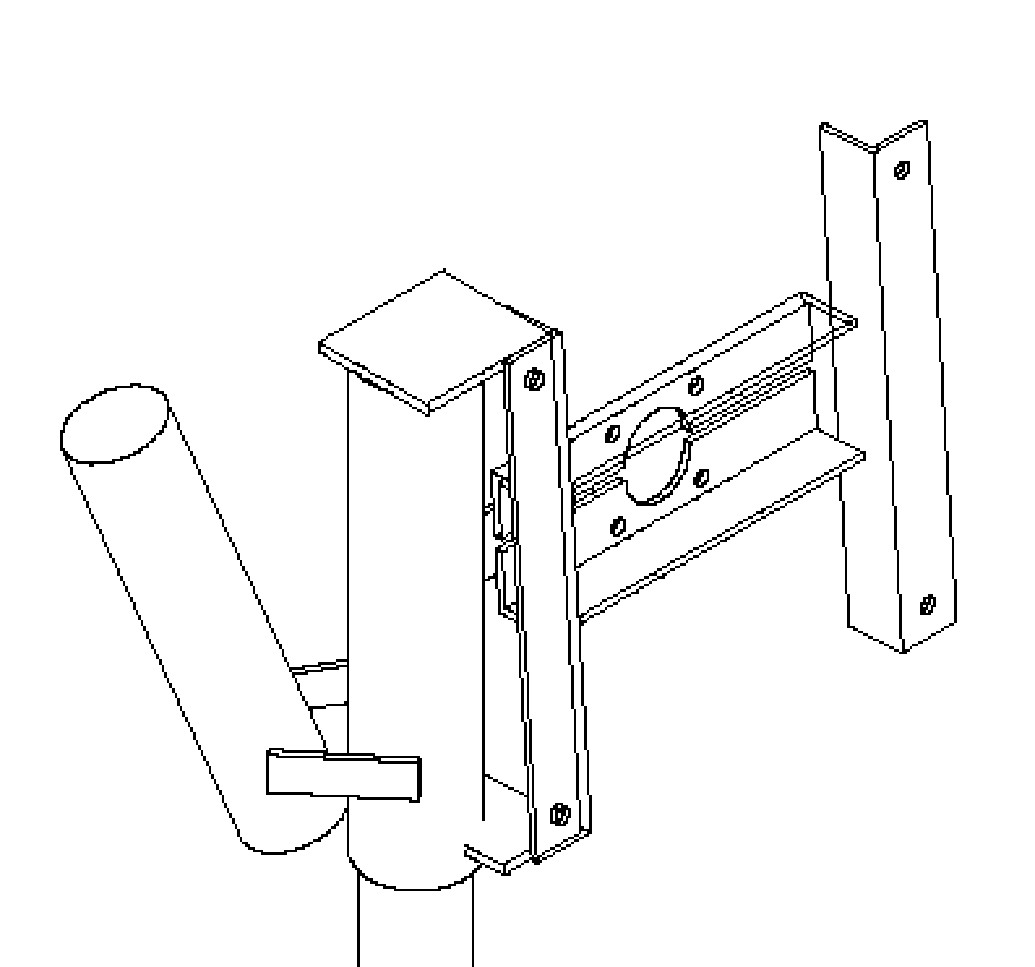

Next time make the supports for the tail hinge much stronger - it's very easy to do. With hind-sight this part should have been more heavily built. It's a part of the machine that often tends to fail if there is heavy vibration or any defects in the welding.

En Francais

En Francais