10 - 14 September 2007

| Main

Gyreum course page |

Blade

carving page |

Metalwork

page |

My

courses page |

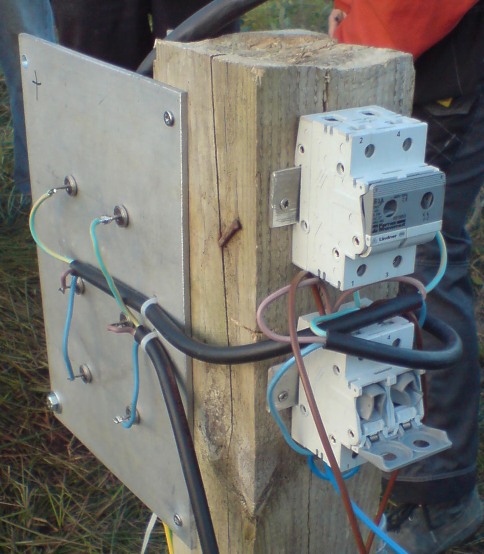

The Electrical department was at the back of the building

| Main

Gyreum course page |

Blade

carving page |

Metalwork

page |

My

courses page |

| Main

Gyreum course page |

Blade

carving page |

Metalwork

page |

My

courses page |