Standing up: Mary Hancock, Jon Priddy, Andy Porter, Uwe Hinz,

Sitting down, Hugh Piggott, Max Oakes.

The smallest course I have done but good fun.

We took down the AWP machine at Shanti Griha just to see what a completed wind turbine looks like and give it a bit of tender loving care.

Click on the photo above to learn more about Shanti Griha where everyone stayed. Uwe and Max brought their partners for a relaxing week..

Uwe came last year, and this year brought Heidi over from Dresden. Welcome back Uwe. Good to have someone around who knows what to do.

The usual drawknife shot. Here Jon wields the blade.

'Kerfing' is not a thing I do a lot of but I recommend it for removal

of the back of the blade where the wood is thick. Andy and Max demonstrate.

Max getting the trailing edge really fine and sharp at the correct

angle.

Andy and Mary drill the hub and magnet plates respectively.

Mary taps out the holes for the jacking screws.

Andy winds a coil.

Welding the frame. Note the tilt angle that prevent the blade hitting the tower on turbulent sites.

Jon sets up the tail hinge at the correct angle and welds it with supreme confidence.

Andy welds the tail itself, setting the hinge end at the correct angle.

Jon uses divider points to mark the corners of the magnets off the

printed page onto the jig.

Uwe puts the first layer of fibreglass into the mould.

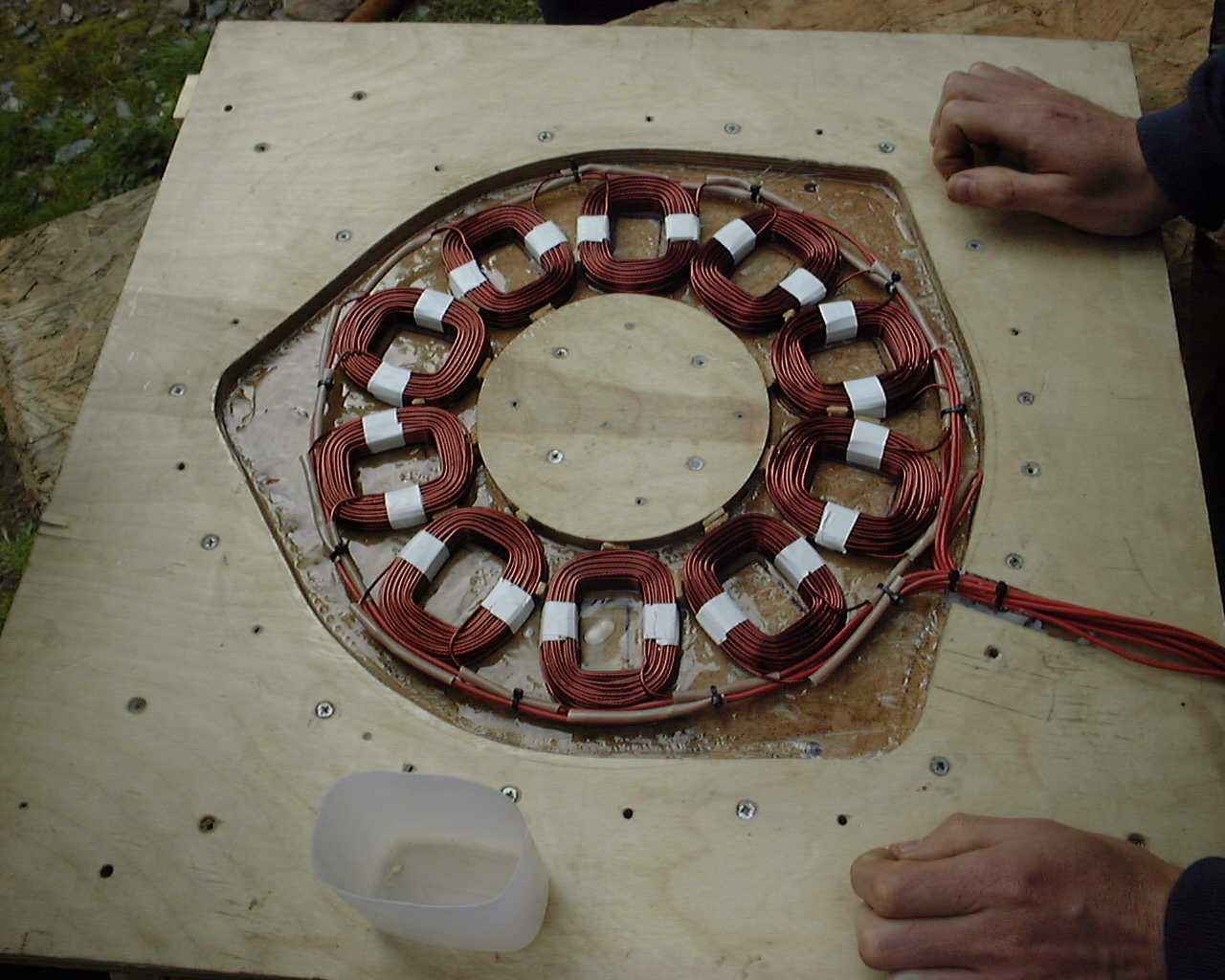

The windings fit neatly into the mould. We use pieces of harboard

to shim them equally away from the island.

Putting lids on the moulds. The spanners (wrenches) hold the

thin board down hard onto the magnets.

Max knocks the stator mould unil the stator falls out.

The completed stator (needs some tidying up).

Then we went for a wander around and looked at windmills on the Scoraig hills in perfect May suhshine.

This is last year's model - shortly to be shipped to Cameroon thanks to John Furze.

The complete machine (blades back disk only). Very neat castings.

Erection time.

Happy ending. Nice crew. Thanks to all.

More courses.