African Wind Power 3.6m diameter wind turbine

3.6m diameter wind turbine

Here is some further information about the 3.6. See also the Powervision

page. The wind turbine is available in battery charging format for 12,

24, 48 or other voltages as required. A high voltage version with

transformers is being tested. Pumping versions are planned.

"Nothing tells you more about

a wind turbine's potential than rotor diameter."

- Paul Gipe

-Wind

Energy

basics, Chelsea Green 1999

Power curve

Here

is the nominal power curve for the 3.6 machine. Power curves vary

between different voltages, and there have not been sufficient funds to

produce a complete set of data, but we are working on it.

Here

is the nominal power curve for the 3.6 machine. Power curves vary

between different voltages, and there have not been sufficient funds to

produce a complete set of data, but we are working on it.

Notice that the diameter of the machine is large compared to it's

maximum

power output, and this gives it the torque to deliver good power in

lower

windspeeds, when other machines are unable to catch as much wind.

We believe it is more important to have a steady, day to day supply of

amphours into the battery, than to have a high peak-power rating.

This is

a 'heavy metal' wind turbine, built for low speed and long life.

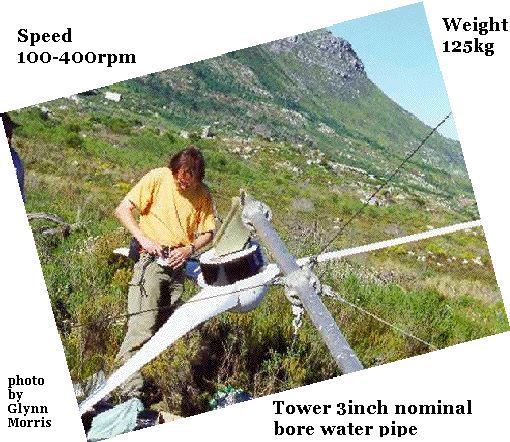

In this picture you can see the alternator (black) and the 3 blades

(white).

The tail had not yet been attached to this unit. Assembly usually

takes place at ground level, and then the tower is erected using a

simple

hand hoist (Tirfor). The tower is supported by steel wire guy

ropes.

This is

a 'heavy metal' wind turbine, built for low speed and long life.

In this picture you can see the alternator (black) and the 3 blades

(white).

The tail had not yet been attached to this unit. Assembly usually

takes place at ground level, and then the tower is erected using a

simple

hand hoist (Tirfor). The tower is supported by steel wire guy

ropes.

Evolution

First

built

for Zimbabwe Energy Research Organisation (ZERO) by Manx

Wind Energy Services

First

built

for Zimbabwe Energy Research Organisation (ZERO) by Manx

Wind Energy Services  (consultants)

in 1996, the wind turbine design was commercialised by

African

Windpower of Harare and badged the pt3600. Detailed design

has

been by Scoraig

Wind Electric throughout.

(consultants)

in 1996, the wind turbine design was commercialised by

African

Windpower of Harare and badged the pt3600. Detailed design

has

been by Scoraig

Wind Electric throughout.

The wooden blades of the original were replaced by fibreglass, and

the tail was simplified.

On

the left is a 1999 production unit from Powertronics. Tens of

machines

have been produced for local customers in Zimbabwe and the export

market.

With the new African Windpower factory, production will be stepped

up.

A 5.5 m diameter machine is actively under development. Smaller

machines

around 2 m diameter, will be available later.

On

the left is a 1999 production unit from Powertronics. Tens of

machines

have been produced for local customers in Zimbabwe and the export

market.

With the new African Windpower factory, production will be stepped

up.

A 5.5 m diameter machine is actively under development. Smaller

machines

around 2 m diameter, will be available later. (click

to see larger image)

(click

to see larger image)

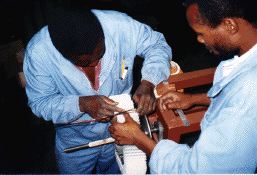

Here

are parts of the alternator. The magnet rotor (top left) is

cast

from iron. It runs on the main shaft. The blades are bolted

to the face this rotor. Inside the rotor are ferrite permanent

magnets.

The magnets move past the laminated core of the stator which contains

stationary

coils of copper wire. On the right you can

see the stator being wound.

Here

are parts of the alternator. The magnet rotor (top left) is

cast

from iron. It runs on the main shaft. The blades are bolted

to the face this rotor. Inside the rotor are ferrite permanent

magnets.

The magnets move past the laminated core of the stator which contains

stationary

coils of copper wire. On the right you can

see the stator being wound.

The alternator is heavy because it has many magnets and coils in

it.

Lighter alternators generally run at higher speed. These lighter

wind turbines are noisier and wear themselves out sooner.

Click to see an

enlarged picture.

Click to see an

enlarged picture.  The

wind turbine is protected against high winds by a simple, passive

system

which has been tested in winds exceeding 100mph, without incident.

The

wind turbine is protected against high winds by a simple, passive

system

which has been tested in winds exceeding 100mph, without incident.

As wind grows stronger, and maximum power is reached, the turbine is

'yawed' sideways from the wind. This prevents the blades from

overspeeding.

There a minimum of moving parts involved.. no springs.. no highly

stressed

components.(click)

Mick Sagrillo writes about

the

AWP 3.6:

This is a very simple machine that does what it is supposed to

do.

It is quite heavy duty and build to last a long time. The turbine

is easy to install, with simple tools. I am most impressed with

the

turbine’s slow speed and quiet operation. It is refreshing to see

that a modern wind generator can be manufactures that is absolutely

quiet

in its operation.

This is a very nice machine. I only wish someone in

the

US

could build something as good as the AWP. We could use the

competition, to

say the least. And the low speed reliability. This is

heavy metal, which

is right in line with my ideas on wind turbine design. Nice

job!!!

The

AWP website in 2009

The

AWP website in 2009

The

AWP website in 2009

The

AWP website in 2009