Small Wind Turbine FAQ

Hugh Piggott October 2006 - updated

June 2007

This is a collection of questions and my answers over the last few

months.

Pretty random really but I thought they might be

useful.

Much of it relates to my designs

and the technicalities of modifying them...

Themes: general (below), blade production, alternators, electrical,

charge control, tails

General questions

I'm just getting interested in wind

power, do you know of any other good sources where I can

learn the basics?

http://www.windpower.org/en/core.htm

http://www.windmission.dk/workshop/workshop.html

http://www.awea.org/faq/

http://www.wind-works.org/

http://www.otherpower.com/20page1.html

What part can small wind turbines play

in the development of sustainable energy-systems for household use?

This would depend on the location and the needs of the household.

If the location is exceptionally windy, then wind energy is an obvious

option. If there is no grid power connected then small wind becomes an

attractive option. If there is grid power available, then it is

possible to buy wind energy from wind farms using much larger turbines

that are more cost-effective. However his/her small wind turbine

can be connected to the grid if this gives the owner

satisfaction. And there will probably be attractive rates

for selling any energy that he/she does not use.

However this small grid-connected turbine will not be able to operate

without the grid, so it will not serve as a back up to the grid if it

fails. In order to be able to provide backup, it would need to be

of the battery-charging (off grid) type which is less suitable for

grid-connection, being more expensive, less environmentally friendly

and less efficient than the simple grid-connected type.

If the location is not windier than average, then small wind is

probably a waste of effort but there is no reason not to do it if the

householder just wants to do it. There is no reason to drive

around town in a big four-wheel drive vehicle, but people do

that. If they need to buy a small wind turbine, then that is fine

too (even better!). But they need to understand that it will not

save them any money (unless the site is really windy). It will be

less environmentally damaging than a four wheel drive, but it will not

immediately 'save the planet'

====

We've just bought a house right on the

North Sea. With the constant wind/breeze I hope I'm right in

thinking we can maximize the benefits of wind power. I can't seem

to find good info on how much power we can expect from a turbine -

hopefully one that is small enough to bypass planning permission which

might be snaky in our little village in Scotland. Can you put me

on track?

You can find out the annual mean windspeed (in the UK) here.

But beware it may not be that accurate especially in built up areas.

You also need to know the swept area of the turbine. Here are

some estimates of energy production at different annual mean windspeeds

per sq metre of area.

mean

Energy

windspeed per year

m/s

kWh/sq m/year

3

58

4

149

5

280

6

434

7

591

For example if the diameter is 2.1 metres. Swept area is 2.1 x

2.1 x 0.875 = 3.5 sq metres

if windspeed is 5 m/s then the energy per year will be 280 x 3.5 = 1000

kWh per year approx.

1 m/s = 2.2 mph

Do you have any performance data or

projections for the 8-foot machine that

relates watts to wind speed?

I have some data from Guemes Island Store. It is mean windspeed

and mean power as in energy production again.

1 kWh per day at 6 mph average, and 2 kWh/day at 8 mph average.

Or, do you have a tip speed ratio and

a way to use it to get m/s out of rpm

data?

tip speed ratio varies

from about 8 at cut in - 7 mph at 200 rpm

to about 6 at 70 watts - 10 mph at 230 rpm

to about 5 at 500 watts - 25 mph and 450 rpm.

====

I was wondering being new to the idea

of homemade wind power how long is a turbine expected to

last. Also how much, and what kind of maintenance is

involved

in keeping them functioning.

They can last twenty years, but repairs are called for now and

then. It's hard to say how often because all builders are

different as are all sites. I would expect a couple of problems

in the first year, and maybe one per year thereafter. Can be just

a blown diode, or can be a new set of blades need to be carved.

====

Can you use a 24V PMG to charge a 12V

battery, the only consequence being lower efficiency because the

charging current is about half what it would be with a 12V PMG?

The speed would be too low and the blades would stall. They would

be unable to get going.

====

Hey -- Doug and I have been talking

about getting his machine up. What thrust value should we

calculate for with that 8-foot diameter axial field machine when we're

trying to size guy wires?

Working thrusts will be about 60-80 pounds but of course the dynamic

thrust swill be many times this in gusts. I would allow at least

200 pounds, plus whatever factor of safety.

====

How do you get the power from the

alternator to the ground. I guess slip rings of some sort.

Do you have a tried and test diy

solution ?

On the whole I prefer to use cables that drop down inside the

tower. they are simpler and less prone to failure on most

sites. On some sites they are a pain but if the yaw bearing is

stiff and the site is open to steady winds, then wires dropped down

inside the tower will go for years without attention.

===

Blade

I'm puzzled. The traditional

design, used for a century or more on farms in this country to pump

water, has a turbine with many more blades that modern turbines,

including yours. Intuitively, this older design, packed with more

blades and surface area wetted with wind, would seem to be able to

extract more energy per square meter. The largest modern turbines

are monstrous, with only 2 or 3 blades, turning very slowly and leaving

most of the swept area empty for the majority of each rotation.

Are these new designs really more efficient and, if so, why?

You need to understand that power is a mixture of torque and

speed. For pumping you need high torque and low speed. For

generators you need high speed and low torque. It is not possible

to get high torque and high speed because there is not enough power in

the wind for both.

If you use many, wide blades, you will get high torque but the blades

will not run fast enough to operate a generator.

High speed blades are few and slender. It may appear that the

wind could blow between them but this is not the case once they are up

to operating speed. In fact they do a slightly better job of

extracting all the available power from the wind.

====

I have searched

through many of websites looking for a good design and understand

a little of the basics, but I'm not really sure what to choose.

Is carving wooden blades the best

option?

In my opinion yes it is the best material to use and if a pleasure to

work with and stronger than any of the alternatives. But you can

use pieces of pipe with success if that is more attractive to

you. It is hard to find suitable wood and some people find wood

carving a bit daunting.

I also found a site showing how to

make a turbine from pvc pipe, <http://www.mdpub.com/Wind_Turbine/index.html> -good idea?

Well it obviously does work. I would expect the blades to crack

and fall off. There is a very bad stress concentration where the

fixing area ends and the wider bit at the root starts. that right

angle is perfact for fatigue cracks. I am not sure whether he

runs this turbine continuously but I would expect those blades to fail

in strong winds after long periods of running. Also the

efficiency is lower than wooden blades with a better shape. But

they work and may be easier to make so why not?

Should I stick with a

fairly standard design?

I am not sure what you mean by this. Using a well designed

turbine will probably be a better plan than guesswork.

Is there a way I could make a good

turbine from junk materials, sort of like I did with the old fan

blades, instead of carving, etc. from scratch?

Old fan blades can work OK. But if they are twisted then the

twist will be the wrong way compared to wind turbine blades. so

try to use straight blades and then try to get the right setting angle

or blade angle to match the speed you are running them at.

Matching the blades to the alternator is the biggest challenge for wind

turbine design. it makes a huge difference if you get the speed

matching right.

====

Hugh, i have some questions about the

carving of the blades: it's about step three (pages 13 and 14 of

your axial flux windmill plans) and where carving the thickness is

explained. Near the root (where the line marking going from station 3

to station 2 leaves the wood and is going into space) i don't remember

how than the extrados ends up into the root of the blade. Can i draw a

line on the extrados from leading edge to trailing edge that connects

the markings made to determine the thickness?

Yes, that is a good rough guide for when you begin to cut. As you

make progress toward the line you can ignore it and focus instead on

1. Having the correct thickness at the line 30% back from the leading

edge

2. Keeping the back of the blade parallel to the front of the

blade.

The lines are only a guide for when you start cutting. The face

you will cut near to the root will not extend from front to back but

this does not matter because the important things are the two rules

above.

How do I carve the airfoil taper on

the leading edge on the blade?

It's clear how to do it on the

trailing edge, but not the leading edge.

The books show the general shape, but

no measurements.

Should I just roughly attempt to carve

that shape, or am I missing something?

It certainly is not critical. If you wish to be exact you could

make templates based on the shape portrayed but generally a bluntish

shape is all you need. I have seen some pretty rough stuff

working well.

It needs a smooth curve. You can measure the angle at the leading

edge and follow that and then radius the edge itself slightly perhaps.

The problem is that hand carving a precise shape is too time-consuming

to be worth it, given that there is a broad range of acceptable shapes.

If you have ever tried to carry an 8x4

feet sheet of ply wood across a building site, its much more difficult

than a piece of 6x2 inch, on a windy day. So why are all modern

rotors long and narrow, and only have 3 blades. The old farm water

pumps had many blades which looked like square angled pieces of tin

plate mounted to look like a wheel. More surface I thought wood equal

more power ?

More surface area makes more force. But for electricity we need

speed. More speed, less force for the same power. Wind has

a certain limited power. So for high speed we use low force and

narrow blades spinning fast. Old farm pumpers cannot move fast.

I have one very simple question you

may be able to help me understand. Why is the three blade prop so

popular? I understand that it is probably faster but with less

surface area comes less force and with less force comes less torque (at

least that's how my mind works). Would a traditional water

pumping windmill geared for higher RPM be a bad idea? More

surface area = more torque in my mind.

You are right in some things, but you do not understand that role

played by torque. This is a common mistake. Torque is the

not the same as power. Power = speed x torque. At high

speed you get power with low torque. A three bladed turbine

produces power at high speed and low torque whereas a pump produces

power at low speed and high torque. The efficiency is similar,

but the high speed one is usually a bit more efficient. It also

saves on the power losses involved in gearing up to high speed.

Gearing is also a lot of extra hassle and expense.

One thought I had whilst reading

through was I notice you use conventional type blades on your

generators, has anyone ever thought or tried more of a turbine type

affair i.e. a tapered tube to increase air speed with a fan located at

the end ?

No but it has been tried. The answer is that it simply isn't

worth all the extra material involved in building a duct like

that. The wind tends to divert around it so you don't gain as

much as you would think. It is actually more effective to build a

conventional blade rotor with larger diameter, than to make a duct.

Can you use a gearbox on the back of

the propellor to increase the velocity of the shaft which you can then

attach to the alternator or other electricity generator type unit

The reason I suggest this was I saw a

bloke attach a gearbox to a waterwheel to increase the rpm as the water

wheel spindle went very slowly. It was a huge increase something like

1:444!

Why cant you use the same principle

before connecting to the generator/dynamo?

Please advise if this idea has any

validity and if it has what type of gearbox could you use.

Yes this is a common approach to the problem with larger

turbines. The friction in the gearbox and the maintenance and

cost issues make it unpopular with small wind turbines.

===

- How essential is it to use leading

edge tape?

not at all essential.

- If it is advisable, then does it

need to be applied along the full length of each blade?

On high winds sites then use it for at least half of the length.

- How do you apply it? I have found

some which is 2” wide, in which case do you lap it an inch either side

of the leading edge?

yes but take great care to avoid trapping air.

- Does the prop’s rear plywood-disc

seat directly against the front face of the magnet rotor, or against

the four nuts that hold the front magnet rotor – as some pictures show?

Or can the whole assembly be held in place by the nuts on the very

front of the prop?

I ride it on the nuts for better cooling and it allows me to adjust the

blade tracking more easily too.

- I am hoping to mount the machine on

a 12m guyed-tower, but the area where I plan to site it is a little

restricted, so how ‘steep’ can the uppermost guy-ropes safely be. I

have tried to estimate some of the angles from some of the pictures on

your website, and they seem to me to be in the region of about 35-40

degrees (taking a measurement from where the guy joins the tower). Is

this about right? What is the absolute safe minimum?

I would try to use 45 degrees with 76 mm diameter or use thicker pipe

say 89 mm overall diameter for the tower. some people have steep

guys with only half the tower height from the base to the anchor.

This is minimum I would say.

==

Alternator

Am I right in thinking for a 12V

alternator I need to connect something that draws 12V for it to spin at

the right speed? for example 12V worth of bulbs (just to demonstrate to

my teacher)? How does the wattage of the thing attached affect how it

spins, and is this why a heater wouldn't work very well?

OK yes you are correct and this is pretty basic stuff.

The alternator's open circuit voltage is proportional to its

speed. At a certain speed known as cut-in it will produce its

nominal voltage (say 12 volts). If connected to a 12 volt battery

it will produce no power at lower speeds. This is good because it

allows the turbine to spin up. Volts without amps means no power,

so no load on the blades.

If connected to a 12 volt bulb or a 12 volt heater the alternator will

deliver current (amps) immediately. These loads will draw a

current at any voltage. You need to give them the correct voltage

to get the rated power. Or lower voltage for lower power.

Not higher voltage, or they may become dangerously hot.

The blades will work best a certain speed range related to the

windspeed range. This keeps it in its 'power band'. If it

is held too slow then it will stall. If it is connected to a load

that needs a higher voltage it will run too fast and produce very

little power that way either. So it has to be correctly matched

to the load. The variables are many: blade design and

diameter, alternator speed and voltage, windspeed, etc etc...

We design or choose and alternator with the correct power/speed

characteristic for the blades. This characteristic will depend on

the voltage but this is usually controlled in some way, for example by

a battery that more or less sets the voltage for the whole

system/circuit. If we can be flexible about the loads and use

control electronics to adjust the loads then we can run the alternator

at any voltage we choose and we can use pretty much any alternator with

any blades (so long as it can handle the power). But this is the

hardest way to go. Using a battery is the simplest.

-------

What kind of reliability record do the

A-F turbines have insofar as you're aware of ? Any common sources of

failure ?

Mainly not too bad.

Poor welding skills and poor blade balance lead to the tail falling off.

Diodes in the rectifier fail due to poor connections and/or poor

cooling. Or due to lightning or similar surges.

In some cases the bearings can give trouble.

Longer term the biggest issues tend to be with corrosion.

Corrosion of the magnet rotor plates is a very serious issue that can

lead to a major failure in under 5 years. The magnet rotors must

be painted very well or the disk/plate must be galvanised if the

turbine is used in a damp climate.

About

mild steel plate for mounting the magnet. Is this a regular iron

that made from metal iron plate? Or, Is it the standard steel

plate? Just like the white shining steel like the spoon

or folk? Have you tried the aluminum plate for

mounting the magnet? Or just by using regular metal

plate bar? What do you think?

Mild steel is the most ordinary steel you will find. Do not use

stainless steel or aluminium - they are not magnetic and it will not

work.

Can I ask one (probably silly)

question - why do the rotor plates that the

magnets sit on in the axial flux PMGs

have to be made of steel? Is it just

for strength or is it do do with

magnetic field/strength?

The disks need to be made from steel. They are used to carry the

magnetic flux from the back of one magnet to the back of another.

It's part of the magnetic circuit, and steel is the best 'conductor' or

flux.

pleas one question. If I take

stainless

steel disks, instead

of steel disks for the magnets, do I

lose a lot of power?

yes that is a very bad idea because the magnetism needs real

steel. If you like you can galvanise it (zinc coating) but I have

never tried yet.

How do we determine the right amount

of separation between magnets when we are spacing them in the rotors

before cast them in fiberglass.I ask because I have seen some designs

in otherpower.com and the magnets are quiet closer if we compared them

with the distance or space that you used in the generator built in

Peru and Sri Lanka.

If you want to get the most power from a rotor of given diameter, place

the magnets close together. If you want to get the most power

from a given set of magnets, place them far apart. Then you have

room for more copper in the coils and you also get less leakage of flux

between magnets.

I found a great deal for magnets

and ordered them.

Well I just realised that they are not

grade N35 but N42 (US version)... does this affect my turns per coil or

wiring size?

N42 magnets will have about 10% higher flux than N35. This means

that the machine will reach cut-in voltage about 10% slower than with

the N35. This is OK and will mean very good performance in 7 mph

winds, but as the wind increases the blades will be going too slow and

it will stall.

There are various ways to counteract this. You can use 10% fewer

turns in each coil. I doubt if this will allow you to use a

larger wire size as the changes in size are nearer to 25%. Or you

can have a larger space between the magnets and the stator. Again

you could make the stator fatter but there will probably not be a

suitable wire size. Or you could even make the blades 10% longer

by increasing all the dimensions 10%. This would give you 20%

more power in any given windspeed below the maximum but would not

increase the maximum output of the machine.

====

First, if they are the correct size,

am I correct in

assuming that the more powerful the

magnets, the

better? I have purchased some

N50s, capable of

lifting 82 lb. each. Let me know

if you have any

comments.

Well stronger magnets do allow you to build a more powerful machine,

but they are not the only way. It may be more cost-effective to

use a lower grade magnet and build a bit bigger.

Second, is there a good reason not to

use aluminium

magnet wire? It would mean a

great deal less weight

for the coils, but would it work as

well as copper?

I have never heard of it being used. the main drawback is that it

would take up more space. It basically has higher resistivity -

you need about twice the size wire for the same resistance. I

don't think it does work out much lighter even in the end.

Lastly, I see some magnet wire is

available with

square cross section. Given that

this would allow

tighter windings, wouldn't it be worth

the extra cost

and effort if it makes for a more

efficient stator?

It's really down to cost. Yes it packs more copper into the

stator, but there may be ways to get as much in by making the machine

bigger at lower cost.

===

Can I use the ("Axial Flux") plans for

the 8 foot pmg to build a 6 foot version, and do you have any

ideas about winding coils as well as magnet sizing for a six foot

version? How can I work out how many turns I will need in the coils,

what gauge of magnet wire to use, and how many coils I'll need in total

too? I want to build a 12 volt 3 phase wind turbine to charge

batteries in winter when my solar array is idle.

I would suggest using 8 magnets 46 x 30 x 10 mm grade 40.

Rotor diameter 233mm

Six coils. Each coil has 80 turns 1.7mm diameter winding wire.

Connect the coils in star parallel. All the starts to a ring

neutral. You can either use 6 wires out, and a rectifier at the

top, or you can parallel the wires of the same phases and bring 3 wires

down to a rectifier at ground level.

Blades scaled down to 3/4 size compared to 2.4 metre version.

Suggested offset from yaw bearing is 80 mm.

cut in speed 280 rpm. You may find that it is prone to stall if

the wiring to the battery is too thick. It's a bit too

efficient as an alternator for such small blades.

You might do better using smaller magnets which would also be

cheaper. The electrical efficiency would be less but the blades

would be less prone to stalling so overall you might do better.

for example you could use 8 magnets 1 x 1 x 1/2" on 170mm disks.

http://www.powermagnetstore.com/acatalog/Block_Magnets.html

use 95 turns of 1.4 mm wire connected in series/star connection.

I have made an alternator and wired it

delta as described in your brake drum book (yes its a bit old but

I like the drum type) a-f b-d c-e and I notice that it

becomes slightly harder to turn when turning it by hand on the work

bench when no load applied to it. when I connect it star it shows no

increased resistance to turning . if I break a connection say b-d

and connect a volt meter between them it shows a small voltage, is this

normal or are the windings not electrically balanced?

Yes this is the main disadvantage of using delta connections.

With a hand-built alternator it is very unlikely that the phases will

be perfectly balanced in voltage and phase angle (timing), so there are

some parasitic currents around the delta itself. This can make it

hard to start up. Once the rectifier starts to work there will be

third harmonic currents as well. So delta is less efficient than

star.

I generally recommend using fewer turns of thicker wire and connecting

them in star rather than using delta if you have a choice.

Oscar can only find ferrite magnets and asks if we could get more power

by using laminated steel in the stator.

Ferrite magnets are probably quite cost effective but mess efficient

that neodymium for their size so the machine is likely to have lower

peak output and the coils will need to be re-designed. I probably

should include a ferrite magnet design in my plans to show how to do it

or he can refer to my free PMG document on the web page.

====

A lot of people ask me why I don't put

a core into the coils in the stator in the axial flux machine.

The advantage of using a core is obvious. A core would reduce the

reluctance of the magnetic circuit by reducing the air gap that the

magnetism has to jump across, and this would result in higher

flux. Higher flux would mean more voltage from the stator at a

given speed, or the ability to produce the same voltage with fewer

turns of wire and hence lower electrical resistance. Basically we

would have a more powerful alternator or at least a more efficient one.

However this performance boost comes at a price. The magnet

blocks would be attracted to the cores in the coils. This would

result in heavy 'cogging' torque, where the rotor jumps from one coil

to the next. Even if this can be smoothed out by clever

positioning of multiple units out of step, there will still be some

magnetic drag on the rotors due to the losses in the cores. This

would affect start-up and low windspeed performance. Even

using laminated cores there is some loss to eddy currents and some loss

to hysteresis.

So my answer is that although you can get more power from a given set

of magnets by using a core in the stator, magnets are getting cheaper

now, and I prefer the simpler, smoother solution with no cores and no

start-up problems.

====

A person that has problems trying to

find the appropriate wire size says that he found a place where they

have 1.5mm or 1.25mm diameter wire, not the recommended 1.4mm for

the 1.2m generator. Which of the two sizes would be the one to be

used? With the same turns per coil?

He should use 1.5 diameter, the same number of turns, but the stator

casting needs to be thicker. Instead of 11 mm it needs to be 13

mm thick.

Are the diodes for the small 1.2m

machine the same as for the 2.4m big one?

Yes I usually buy the 35 amps diodes for all turbines. It is

possible to save some pennies and buy lower current diodes. But

there is more safety factor if the diodes are rated 35 amps and 800

volts or so.

You say that it must be 'Flexible wire

with high temperature insulation 0.75mm bundled in a protective sleeve'

Can you

give me the name and phone

number of a place where I can buy it?

I don't know where you are :-)

Here in the UK I prefer to use "tri-rated flex". But even pvc

coated

flex would work fine I am sure. Automotive stuff would be fine.

====

I'm a bit confused on the

specification of the correct cable to use in wiring the neutral ring in

the stator and output from the tails of the windings. In your book you

specify:

"Flexible wire with tough,

high-temperature insulation" 14 gauge or 2.5mm"

does the 2.5 mm refer to the diameter?

no, in the case of other types of wire the size is a cross sectional

area. 2.5 sqmm is a common size.

What type of current and voltage

should this cable be able to handle? e.g 30amps 1000volts?

(My windings are 1.6mm magnet wire)

To be honest it is not that critical, but I recommend the neutral and

the tails should be as big as the magnet wire in other words 2

sqmm. 2.5 is a common size. I like to use tri-rated flex

but ordinary pvc covered flexible cord will do.

==

My question

is what is the purpose of the use of talcum powder in the resin?

I was unable to find the answer in the book or on my own in talking to

people in the trade of using the fiberglass resin.

Talcum powder is used in the resin casting for 4 reasons:

1. It moderates the heat of the reaction, so that the casting does not

get so hot and therefore does not shrink and crack as it cools.

Nor is it so likely to overheat during the pouring process and set

prematurely.

2. It alters the thermal characteristics of the casting - makes it

better at conducting heat when the coils are working hard, and keeps

the coils cooler, allowing them to carry more current safely.

3. It is much cheaper than resin so it saves on cost.

4. It thickens the resin so that it does not leak out of the mould so

fast if there are minor leaks around the edges.

====

Hugh,

My wind generator project is moving

forward nicely. I’ve reached the steps where I’m starting to

fiberglass things in and was curious why do you add Talcum powder to

the mixture? Is it a problem if I just use fiberglass resin only?

In a practice mix, I found it very difficult to get the Talcum

powder mixed in without creating clumps and introducing air bubbles.

Talcum powder is important, yes, Mainly it is there to moderate

the heat of the reaction. Without fibreglass the mix tends to

heat up too much in the mould, and when it cools it warps or

cracks. It an also start to cure prematurely. Talcum powder

also makes the mix less fluid so it does not tend to run out of the

mould so easily and it is also a lot cheaper than resin. Putting

it id does introduce a bit of air, but so far I have never found this

to be a problem in fact.

======

I'm thinking of building a 12' wind

turbine. the site is a long way from my house so I want it to have a

high voltage. your plans give specs for 12 volts. two wires, 25 turns

#13 awg. I assume one wire, 50 turns same gauge wire would give me 24

volts. in your table on page 4 of how to build a wind

turbine, the relationship between wire size and the number

of turns doesn't seem exactly liner. Since I'll be producing

AC courant it makes sense to start with a high voltage and

step it down at my house. Do you have any reconditions as far as

wire size, number of turns per coil, expected voltage, how high is

reasonable to go, and transformers. I've also noticed that for

some alternators you specify different strength magnets. for the 12'

you specify N 35 magnets. why not stronger magnets. I realize that the

alternator is designed to work with the blades. I don't want to build

something that is out of balance.

I love wind mills and I love

building things and I think that your book and the whole concept of

building a windmill including carving blades and making an

alternator is the coolest thing ever. WOW!

Broadly the number of turns is proportional to voltage but in some

cases the high rectifier volt-drop at 12 volts skews it, and the

availability of wire in certain sizes.

For 120 volts you could use 220 turns maybe.

If you are using transformers you have the advantage that you can use

tappings to do fine adjustment to speed. The danger is of running

too fast at cut-in or of stalling in stronger winds from being too

slow.

You may find that the turbine has problems starting up when connected

to the transformers. Use a relay to disconnect them at low

speed. You can run the relay off a second rectifier or even

perhaps directly off the AC of one phase (but this will buzz).

======

Just received your plans how to build

a wind turbine, thanks

On page 49 you have plans for a 10

foot, 24vdc unit..

Is it possible to change the windings

to create a 12vdc unit

with the same 9 coils. if so could you

email me with the

wire size and the number of turns?

I would suggest 105 turns in each coil. Use 15 ga wire or 1.4 mm

diameter. A single wire in the coil (not 2 in hand) But the

3 coils are in parallel. You can either parallel the 3 coils in

each phase and bring them down to the rectifier in 3 wires, or you can

put nine wires into the rectifier as in the ten coil version. the

latter is slightly more efficient unless the 3 coils are truly

identical in shape and perfect in location.

---

Electrical

Can your generators be linked to

supply the grid when its very windy ? I believe there are lots of

electronic gadgets for phasing etc or is the cost too high?

Yes they can be linked. This technology is advancing very

fast. The preferred solution is the SMA 'windy boy" inverter.

Can I mention 3 phase?

yes of course. I normally use 3-phase. But 3 phase does not

necessarily mean high power and volts. Car alternators use

3-phase.

What is done to prevent the twist of

the out put cable as the turbine changes direction?

the cable will twist. My philosophy is to make the cable

sufficiently robust and flexible to accommodate several years of

twist. On sites with a certain kind of turbulence, this does not

work and you either need a plus and socket to untwist it periodically

or you have to fabricate sliprings. However these have to be well

made or they cause more problems than the cable.

I have been enthusiastically building one of your design generators (8

foot version) and all is going well, however I was a little confused

about the type of cable used for the tower drop! Is there a

particular cable I can use with anti twist capabilities and if so do

you have a supplier, or is the twisting of the cable not as big a

problem as I am imagining ???

The amount of twist depends a lot on the site. But if the yaw

bearing has a little friction as is normal and the site is good (not

too turbulent) then twisting should not be a problem. check for

twisting from time to time and if it looks like damaging the cable then

disconnect and untwist the windmill in calm weather.

I would recommend the use of single wires rather than a combined

cable. Flexible wires are best. I like 'tri-rated' flexible

wires here in the UK. Expensive but the insulation is very tough.

Building of the wind tubing is now

complete, and 12 metre pole is up and guyed, what i want to know is,

what size fuses do i use on the ammeter, volt meter, and between

inverter and charge controller., and where can i get them from ,

the system is 24 volt. ( pic page 43)

Generally speaking the fuses need to be coordinated to the cables you

are using so there is no danger of fire. for functional reasons

the fuses also need to be large enough that the normal operation of the

system does not blow them. Usually a 1 amp fuse if fine for the

voltmeter. For the inverter, follow the instructions.

Similarly the charge controller will have a rated current and the wires

should be sized large enough that fusing is easy for that.

The wind turbine fuse is a more difficult case. In theory the

current should not exceed about 20 amps, but in reality it may reach

high levels (50 amps) at times and it is undesirable if the fuse blows,

because then it will overspeed. It is therefore a good idea to

have thick cables and avoid short pieces of smaller sizes without good

cooling. High temperature insulation can allow the use of smaller

wires. If the wires become twisted then there is a good chance of

short circuit and blowing the fuse. In such cases you need to

apply the brake switch and wait for suitable conditions to untwist the

wire. Normally it should be untwisted before this happens.

Forklift truck fuses are available from RS and Farnell on the

web. Automotive fuses can also be good but beware that they have

limited overload tolerance.

The generator i have at the moment is

a lister start a matic, of 2 1/2 kw, charging 2 x 200amp hr batteries,

(fork truck batteries), the charger is 50 amp, working 12 hours

on and 12 hours on inverter, can i connect my morning star ts 45

, straight onto this set up, would there be a problem when generator

and charging, and the wind turbine going as well, or would the charge

controller prevent any problems.

The charge controller will prevent battery problems but you may find

that it starts to dump power into a heater when the generator is

running. This may not be fuel-efficient. You maybe able to

get around this by adjusting settings. You can even use a relay

off the generator to adjust them for you if you can cope with the

complexity. Switching a diode or two into the battery voltage

sensing circuit of the controller can be effective in preventing it

from dumping when the generator is charging hard. Much depends on

your battery management strategy.

===

I am contacting you with regards

to the booklet called 'How to build a Wind Turbine'. 8ft 8oowatt

February 2004

page 39 brake switch. What sort of switch

Single pole changeover (2-way) switch capable of carrying the full

current say 50 amps. Not that easy to find actually. You

can also simply use a system of disconnecting and reconnecting to the

negative wire. this is easy with a bolt and lug connection

system, and wing nuts on the bolts.

What size blocking diode

this is optional. It is good for preventing over-voltage during

the process of changeover but in the case of 12 volt systems the max

voltage is only about 50 volts which is not life threatening.

What size fuse

At least 50 amps for 12 volts. Actually it is determined by the

cable you have chosen and must be chosen so that this cable cannot

overheat.

Where to get a trace c-40

I can sell you one. Nowadays I prefer the Morningstar Tristar 60

controller for 12 volt applications. Cost is £140 plus

delivery and VAT.

====

I am currently building a 10 ft dual

rotor pmg, I may be getting ahead of myself but am considering putting

as much power as possible into water heating elements

Heating is usually less valuable energy than electricity so I normally

use it to dump unwanted power myself. But a battery etc is extra

cost and hassle if you are on grid. These turbines are rather low power

so they work well for heating water but will not make a big impact on

space heating.

I am wondering whether it is more

efficient to use your taco control circuit with wild ac

or rectifying to battery storage and

dc to heating elements with a charge controller + dump load

my system is wound for 24 v 3

phases

what is the best arrangement for connecting three phases to heating

elements after taco cuts in and how does affect the pmg loading v

furling

I would be interested to know what you

consider to be the most efficient use of wind generated power

The tacho triac system is normally used with about 200 volts and

multiple small heating elements. It won't really give much more

heat than a battery charge controller, although in theory you should

get better alternator efficiency by operating at varying voltage in

stronger winds (which is not feasible with battery connected

systems). I would recommend using a battery and a charge

controller for simplicity and to provide a stable electricity source

for other purposes unless you have no interest in electricity as

such.

Charge controllers like the Morningstar Tristar 45 only need one

heating element and they control the amount of power diverted to heat

in the load. This is simpler and smoother than switching on and

off multiple small elements.

===

Battery & charge

controller

I am currently working on the shunt

reg cct but am

slightly confused about its setup. I

assume it is designed to shunt power

away from the battery strings when

they are fully charged to prevent

damage? If this is the case could you

tell me in what way you would expect

to setup the presets please.

good point. Nobody has asked that before.

You can either wait until it is windy and do it by trial and error, or

you can use a variable voltage supply. The circuit I use is shown

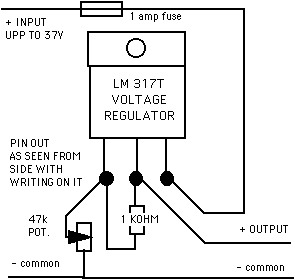

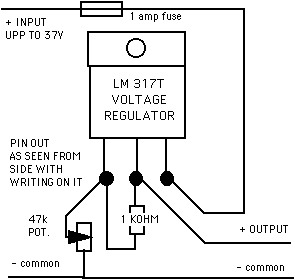

below. the pin-outs are as seen from the side with the

writing. You may need to fix it to a small heat sink.

I also assume that I would need to

source a controller to equally ensure

the battery strings do not get too

discharged to prevent permanent damage.

Yes if you are not able to supervise it to some degree.

supervision is usually better because it causes less disruption.

Use less power when the battery voltage falls. Your inverter will

cut out at some point anyway. This is usually automatic to

protect the battery although the voltage it happens may be quite low.

I am building your charge controller

circuit. I am not an electrical genius and admit i really

don't understand how it works. But i do have two questions---one--once

hooked up to a good stable power supply --what is the proper procedure

for adjusting it.

I would normally try to get it to turn on at 14.5 volts and turn off at

13.5 volts. The capacitors slow things down. I would set

the voltage at 14.5 and then when it has had time to settle I turn the

10k potentiometers very slowly until it clicks on. then I turn

the voltage down slowly until it clicks off. If the gap is too

small or too big then I adjust the 100k pots to adjust the

hysteresis. then I have to set the 'on' point again

usually. I am not too bothered about the off point but if it is

too close then it switches too often and wears out the relays. If

it is too low then it dumps for too long and discharges the battery.

And what voltage would you recommend

it be set at --high and low? for a 12 volt system using 4

batteries.

Depends on battery type. "flooded' batteries with acid in liquid

form I would set higher than sealed batteries. Traction batteries

you could set as high as 15 volts if they do not spend a lot of time

fully charged. Normally 14.5 volts on and 13.5 volts off works

fine.

The comment that inspired me to write

related to your dislike of batteries. I too don't like batteries

either. With that in mind, I have been looking into other energy

storage techniques.

I have been thinking about this for a

bit but haven't gotten it past the idea stage as of yet but I wonder if

you might comment on the concept.

The idea I have it to setup a test

system that uses a windmill/turbine to turn a compressor and store the

energy as compressed air. On the generation side I was thinking of

running generators off of air turbines, possibly little ones where the

power is actually needed. Distribute the compressed air via high

pressure hoses and then generate the power as needed on the spot.

The main problem here is the low efficiency due to loss of heat in the

storage vessel. I think it can work well in large underground

stores and is use for such in gas turbine plant in Texas using oil

wells that are empty) but on the small scale it is hard to see how to

deal with the thermal losses.

I am now looking at the homebuilt

battery charge controller – both on your website and in the book.

Please could you answer a few questions?

sure.

1. The booklet

suggests 2 circuits are required whereas the site seems to indicate one

will do the job- is this just dependent on the rating of the

relays/loads?

More circuits makes for smoother operation. Voltage fluctuates

more slowly and the relays last longer by switching less often.

2. Are any changes

required (apart from the dump loads) for the smaller turbine?

No. I would use 2 small dump loads.

3. Would the idea

be to set the 10K pots so that the dump loads come in at e.g. 14V and

15V

and the 100K (500K) pots to turn the dump loads off at X and Y volts?

The setting of the 100 k pots is the feedback and it determines the gap

between on voltage and off voltage. Set it in a mid range

position. Set the 10 k so that the load comes on at about 14.5

volts. Set both the same more or less. One will come on

first but they are both at 14.5 volts or thereabouts. As the

volts fall, the relays should turn off at about 13.5 volts.

If this is not the case then you can do some fine tuning with the 100k

pot and then possibly adjust the 10 k again.

4. My understanding

is that without a charge controller the generated DC voltage is held

down by the battery.

Yes, this is always true. the charge controller just influences

the battery's diet.

Tail

I do not understand if the tail should

be welded at a vertical

angle or if this even matters.

Also how do I know how the

length of tail, area of tail, angle

offset of the tail, and

weight of the tail will interact to

overcome the friction of

the pipe and the gravity of the tail

weight at the correct

wind speed. Any assistance you

could provide would be greatly

appreciated.

The tail vane can be mounted off-vertical and this may have some effect

on the system but not much. I try to keep it vertical for

aesthetic

reasons.

Length and area need to be sufficient for it to work as a tail and to

hold the rotor into the wind. This will depend on rotor size,

offset

and also on yaw bearing friction.

The angle of offset of the tail is to counterbalance the force of the

rotor in normal winds. It is not critical.

Weight of the tail directly controls the maximum power output.

Friction of the pipe influences the stability of the system and the

accuracy. A little friction is not bad, but a lot will mean that

the

tail tends to get stuck at low output when wind drops a bit.

Other (more important) key factors are the angle from vertical of the

hinge ( which has the same effect as weight) and the orientation of the

hinge seen from above. The hinge points a little sideways (side

angle)

and a little backwards (back angle) on the turbine. The side

angle

influences when it starts to furl, and the back angle controls power in

stronger winds.