POWER 4000 watts at 220 rpm

28 magnets per rotor 46x30x10 mm ND40

Magnet rotor diameter is 588 mm

Jonah fits the magnets using cyanoacrylate glue.

We put strips of wax into the casting to make channels for air between

the magnets. Alan removes them below.

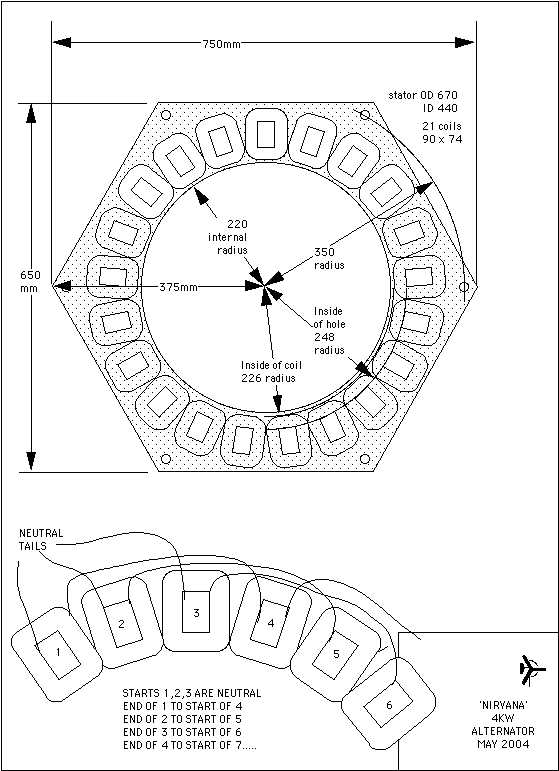

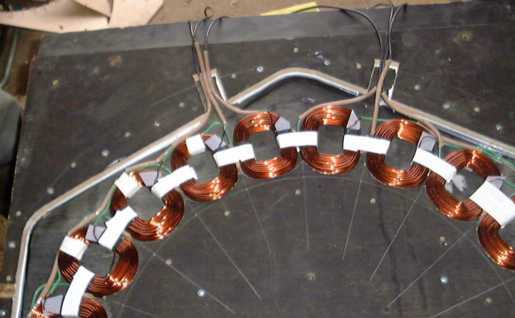

Stator has 21 coils. Each with 100 turns of 1.4 mm wire. Connected series star.

New concept star shaped island for best coil cooling.

Sliding the coils off the try into the mould.

Alan vibrates bubbles out of the resin mix with an SDS drill.

Turned out nice.

Alan welds stator mounting brackets. dummy used to support predrilled lugs.

Better to drill holes after welding distortion is complete :-)

about 70 volts AC at 60 rpm. 40 mm spacing between magnet plates.

Tractor testing time...

We mounted it at the workshop door and drove it with the pto using a plywood adapter.

We got 4 kW at 200 rpm this way but it soon began to smell pretty hot.

Running at a slightly higher speed and voltage would reduce the losses but I was mainly relying on the wind to cool it better.

see page 2 for what happened next....